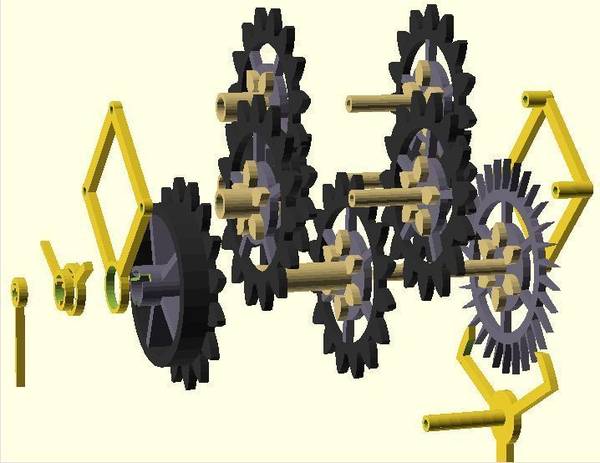

After a season of intensive, public experimentation and iteration, Thinigverse user Syvwlch has completed and uploaded a design for a working, 3D-printable clock that can be output from a cupcake Makerbot printer (these being DIY, open source 3D printers that can output things about the size of a cupcake or smaller).

Syvwlch's work on a printable clock has been one of the most exciting ongoing projects on Thingiverse. He's just upload what might be a final version of his work. This version includes the escapement, pendulum, gears for the seconds, minutes, and hours, and a set of nested concentric gears to provide the corresponding second, minute, and hour movement. And, let's not forget he's made this entire clock parametric in OpenSCAD – in case you need to print up a grandfather clock or a teeny-tiny watch.

Syvwlch's Printable Clock – ready for printing!