Chris sez, "The oft-touted promise of 3D printing is of personalisation and customisation. There is an alternative use though which is that of mini and micro-manufacture, where production runs of things numbering hundreds and thousands are suddenly made possible and in some cases commercially viable.

"We're investigating this space as a new way of manufacturing model kits, using laser scanning to get the data for the prototypes to make the kits very accurate. The financial advantage of 3D printing in producing kits at whatever scale people want to model in, often from the same file, is huge and makes the creation of very niche items viable. We're experimenting with crowd sourcing what potential kits to explore and using crowd funding to decide what to focus on and make."

Chris and co are scanning full-sized railroad engines at insane resolution.

We realised though that some things that you want to model were too complex even for incredibly talented CAD model makers like Vijay to create perfectly just from photographs, or at least that the time taken to produce the model would be too long and the process of checking the model's fidelity would be too involved and too risky. We looked into 3D scanning and found a firm, Digital Surveys, who normally scan petrochemical plants and oil rigs and who specialise in "as built" surveys.

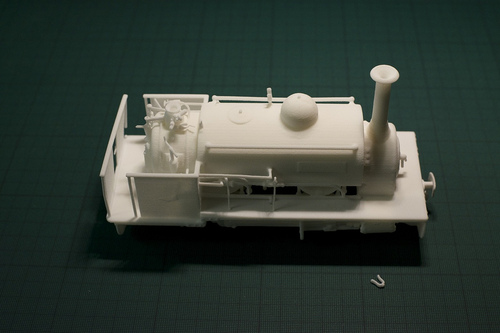

They worked with us to scan Winifred, a steam locomotive that had just returned from the USA in an almost identical condition to that she left the quarry in Wales in 1965. The survey, 3D model and 3D printed model that ensued showed us that we were on the right track…

…p.s. this data is too precious to lock it up, so we're working on opening up the original data and the CAD files of individual parts with other manufacturers (of wheels and parts) and railway societies who are keeping the real things going!

(Thanks, Chris!)